Application:

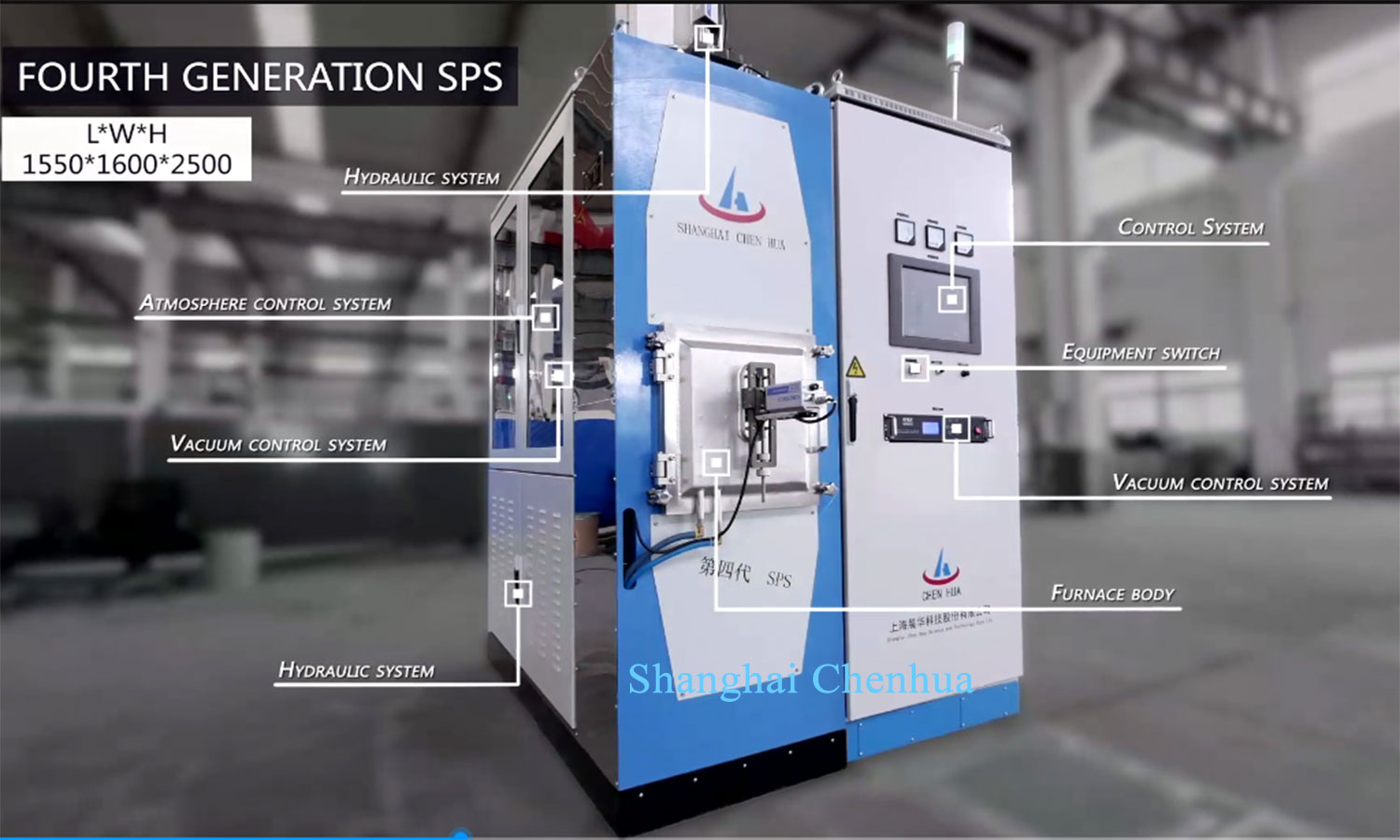

SPS fast pressure sintering system is one of the most advanced fast hot press sintering systems in the world,

characterized by the fast sintering speed and high density sintering. It is the most powerful tool used to sinter

the nanophase material, gradient functional material, mesoporous nanoscale thermoelectric material, rare earth

permanent magnetic material, alloy glass nonequilibrium material and biological material.

Features:

More accurate temperature measurement:

1. 4th generation SPS furnace uses the imported double-color infrared thermometer used to directly gauge temperature

of workpiece center, which gets more precise value of temperature so as to produce the satisfactory workpiece.

Lower energy consumption:

2. 4th fourth generation SPS furnace takes advantage of high strength low resistance electrode material, non-water

cooling mode to conduct the electricity, punch configuration to bring the energy inside the center,which gets faster

speed of temperature rise under the condition of equal current.

Advanced integrated power supply:

3. 4th fourth generation applys the complete digital pulse power supply that is controlled by mini computer, while using

mini rectifier transformer made in Britain can gain the control of the idealized pulse parameters.

4. Control cabinet integrated with the furnace, top pressing mode, rational structure, simple operation.

Main technical parameters:

| Model | Rated power | Output current | Input voltage | Max. temperature | Max. pressure | Sample size | Punch displacement | Final vacuum |

| SPS-5T-5-IV | 50KW | 0-5000A | 0-10V | 2300℃ | 10T | ?30mm | 100mm | 10-3Pa |

| SPS-10T-6-IV | 60KW | 0-6000A | 0-10V | 2300℃ | 20T | ?50mm | 100mm | 10Pa |

| SPS-20T-10-IV | 100KW | 0-10000A | 0-10V | 2300℃ | 20T | ?100mm | 100mm | 10-3Pa |

| SPS-50T-30-IV | 300KW | 0-30000A | 0-10V | 2300℃ | 50T | ?200mm | 200mm | 10Pa |

Online consulting customer service

Online consulting customer service